FAQs

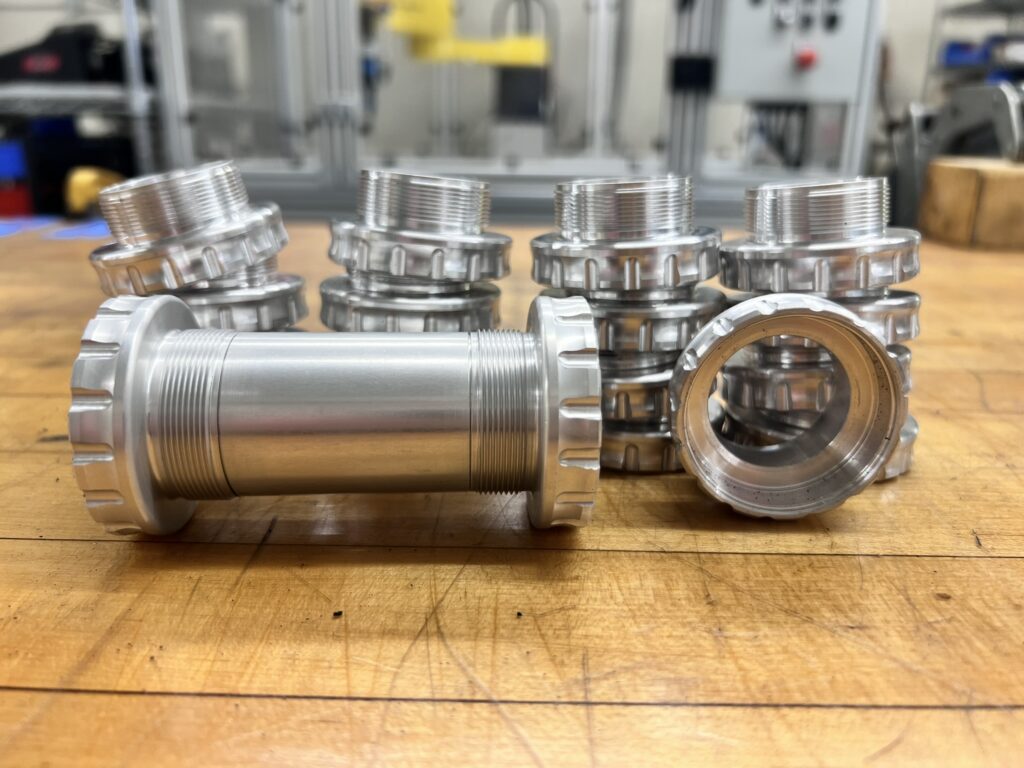

Where are your Bottom Bracket cups made?

Our Bottom Bracket cups are made right here in Connecticut using either aircraft-grade 7075

aluminum alloy or Grade 5 Ti-6Al-4V titanium.

Where is the anodizing done, and are custom colors available upon request?

Anodizing is done right here in Connecticut at one of our manufacturing partner’s locations, and yes custom colors are available upon email request (fee applies).

Why should I pay extra for ceramic hybrid bearings?

Ceramic hybrids roll faster, are more corrosion resistant, and pulverize small amounts of

contaminants in the raceways.

Why choose titanium for a BSA cup over aluminum alloy?

Titanium is significantly stronger than aluminum alloy. BSA cups have limited material

where the cup flange meets the threaded part of the Bottom Bracket cup, so material strength is key. Titanium offers more stiffness and resistance to misalignment than aluminum alloy. Titanium is also extremely corrosion resistant even without anodizing, and they look damn sexy, too.

What’s the deal with the hot dip chain wax?

Our proprietary wax hot melt is a custom mix of two different types of American-made

Paraffin wax and three specific micro sizes of tungsten disulfide (WS2) dry lubricant particles. In crafting our wax hot melt, our goal was to save between 5-8 watts over traditional wet lubes, achieve better adherence, and offer better longevity and value than our competition.

What’s the deal with the polished bearings?

We offer polished bearings in both traditional and ceramic hybrid versions. Our proprietary

isotropic polishing process first uses chemicals to soften high/rough areas in the bearing

raceways left by machining and grinding. Next, the bearings are polished with ceramic media to remove the high spots. The process is repeated until the surface is super finished and micro-textured. The polishing process decreases rolling resistance and allows the lubricant to be better retained inside the raceways.

What brand of bearings do you use in your Bottom Brackets?

We start with the best Japanese bearings from NTN or NSK and upgrade their performance

through an in-house service. We painstakingly remove the balls, cages, seals, and stock lubricant.

After disassembly and cleaning we inspect, re-assemble, and refill the bearing with one of our application-specific greases. If selected during checkout, we also can add ceramic balls and super finish the bearing rings.

Does your hot melt wax lube contain PTFE or PFAS?

Heck no! PTFE is a frequently used long-chain polymer lubricant and also a very common

dry additive in bicycle chain lubes. Fortunately PTFE is consistently outperformed in every

applicable area for bicycle chain lubes by the much safer WS2. The risk of PTFE being

overheated in a hot melt formula (changing it to a potentially dangerous short-chain polymer) and releasing PFAS emissions is too high for us to include it in our product.

Do you guys offer a hot melt waxed chain ready to install?

Yes! We offer 5 options:

- SRAM T-Type XX

- SRAM Eagle XX1

- SRAM Flat Top Red

- Shimano 12s XT-Ultegra

- Shimano 12s XTR-Dura Ace

How do you recommend melting the wax?

You should use only dedicated wax melters to melt your hot wax lube and always follow the

manufacturer’s directions. We personally like the Silca wax melter but other paraffin wax

melters are available online. Never heat our wax above 185° F (ideally 165-175° F). Never melt

our wax near an open flame.

What Bottom Bracket standards do you make?

We currently make BSA MTN, BSA road, and t47 internal road. We also make spindle

reducers for 24mm and 29mm spindles. Additionally, 30mm spindles fit directly in our Bottom Brackets without a reducer.